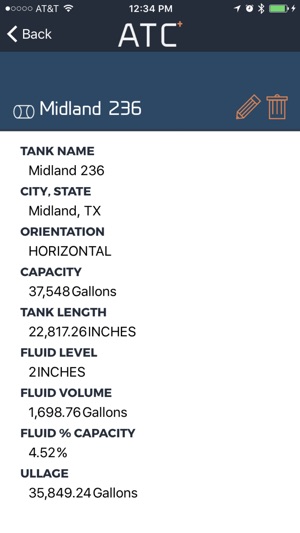

For calculating the tank capacities only, it is not required to give a draft. Calculate tank particulars. An input screen appears for defining all tank particulars, such as sounding or ullage, volume, density and weight. If one of these items is changed, the other items will be adjusted automatically. Ullage/ Sounding just reciprocal to each other. Ullage is the volume that is left empty in a tank so that there is space for the liquid in the tank to expand. The air space between the oil surface and the top of the tank is known as ullage. And sounding is just opposite. We have undertaken smaller projects too - Ullage reports only for crude and product tankers with results exported to charterer's and owner's standard forms (ship specific data for tank volumes with trim and heel correction, stability, stresses and hydrostatic calculations, etc.

As I have requested by comments to post about Wedge Formula of liquid cargo measurement, herewith the article collected from internet

What is Wedge Formula?

Wedge Formula is calculation to determine the small quantity of liquid or non liquid cargo (On Board Quantity – OBQ or Remaining On Board – ROB) on cargo tanks, where it should fulfill the following conditions :

– The vessel has huge trim, but there is no trim correction value available on the tank table,

– The liquid or cargo on tank is not touch one or more of the tank bulkheads,

– Observed sounding tanks at several points to ensure the cargo is not touch one of the tank bulkheads,

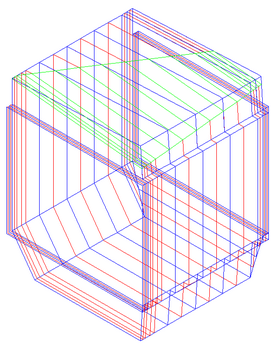

In order to standarise the OBQ/ROB calculations on board the Crude Oil carrying tanker vessels, the following geometric form of the Wedge Formula shall be used and this form of the formula assumes that the cargo tank is ‘box shaped’ with no internal ‘deadwood’ or pipeline systems, heating coils etc. that would impact the accuracy of the volume calculated from the sounding. Furthermore this wedge formula calculation makes the enormous assumption that any ‘liquid’ found in a cargo tank is in the form of a regular wedge shape with its base at the aft bulkhead of the cargo tank.

It is obvious that such a series of assumptions normally can invalidate the absolute accuracy of the calculation immediately given, amongst other issues, the shape of the wing tanks (the turn of the bilge) and in particular those wing tanks at the fore and aft parts of the vessel.

The calculation method for the Geometric edition of the Wedge Formula:

Assumption: Given the small angle involved with the trim of the vessel, then the ‘Sine’ of an angle can be considered as the same as the ‘Tangent’ (Tan) of an angle and consequently:

Step 1:

Correct the position of the sounding position with respect to the aft bulkhead of the cargo tank due to the trim of the vessel, distance = A

A = Tank Reference Height (Observed Height) x Tan X;

where X = the Trim angle of the vessel and;

Tan X = (Aft draft – Forward draft) / Length Between Perpendiculars (L.B.P.) of the vessel.

Step 2:

Determine the distance of the apex of the wedge from the aft bulkhead for obtaining information whether:

(1) Should a Wedge Formula be used at all (kindly note that a wedge formula is not applicable if:

(a) the liquid surface covers the total cargo tank bottom or the calculated apex of the wedge is at or beyond the forward bulkhead of the cargo tank or:

(b) it is sludge ROB volumes only);

And

(2) Whether the wedge is a regular wedge (which can be checked by comparison with alternative soundings being taken).

S = Observed Sounding;

F (Distance of the apex of the wedge from the sounding position) = S x Tan X;

E (Distance of the apex of the wedge to the aft bulkhead) = (F – A) + B;

where B is the distance on deck from the point of sounding to the aft bulkhead.

Step 3:

Determine the depth of the wedge at the aft bulkhead of the cargo tank, depth = D; D = E x Tan X

Step 4:

Knowing D (sounding depth at the aft bulkhead) and E (the distance from the aft bulkhead to the apex of the wedge), then the area of the longitudial cross section of the wedge may be calculated,

thus as the area of a triangle = (Base x Height) / 2 then; (D x E) / 2 = cross sectional area of wedge.

Step 5:

Having obtained the cross sectional area of the wedge, the volume of the wedge is calculated by multiplication by the breadth of the cargo tank (please note that the breadth of the cargo tank should be measured at the bottom of the tank at the aft bulkhead position and not at deck level or elsewhere within the cargo tank).

Volume of the Wedge = Cross sectional Area x Breadth of Tank

Throughout this calculation it is very important that all distances are in metres. Do not use centimetres for the observed sounding.

Alternatives

Regardless above stated requirement, an I.S.O. standard method is also available in the event that any Cargo Inspector do not accept the geometric edition of the wedge formula. This method depends upon the accuracy of the vessel’s tank ullage calibration tables for the larger ullages / smaller soundings in the cargo tank. If the tank calibration tables are accurate for this region of the cargo tanks, then this method will give added accuracy to the general method of calculating tank residues after discharge.

This method is as follows:

Step 1:

Calculate DA (the Corrected liquid sounding at the aft bulkhead position); DA = D + {f(Y – (H x f))}

where:

D is the observed liquid sounding;

f is the Trim factor ( TS / LS );

TS is the vessel’s trim;

Y is the distance of the sounding point to the aft bulkhead;

H is the reference height of the cargo tank;

LS is the vessel’s Length Between Perpendiculars.

Step 2:

Calculate Ct (the Tank constant); Ct = LS / ( 2 x TS x Lt ) (where Lt is the Length of the Cargo Tank).

Step 3:

Calculate the ‘k‘ coefficient; k = DA x Ct

if k > 0.5 wedge is not required to be carried out;

if k = 0.5 wedge must be carried out.

Step 4:

if k > 0.5 then calculate the volume of the liquid contained in the cargo tank from the calibration tables using the Observed sounding, D, applying the trim corrections.

Step 5:

if k = 0.5 then calculate DX (the wedge sounding). DX = DA / 2

Step 6:

Enter the cargo tank calibration tables with DX, without applying trim corrections to equivalent volume VO.

Step 7:

Calculate the liquid wedge volume V1; V1 = VO x 2 x k

In addition to above methods it should be noted that if the procedures as specified in the vessel’s COW manual are being followed for the determination of the ‘Dryness’ of a cargo tank, namely, the sounding of the residues in four (4) differing locations within the cargo tank, then the foregoing methods of calculations can be avoided.

Assuming the shape of the individual cargo tanks is fairly regular / constant in a fore and aft direction and, notwithstanding the fact that the vessel will be significantly trimmed by the stern, then the four measurements, as suggested in the COW Manual guidelines, as obtained by sounding can be used to calculate an average sounding so as to obtain a single sounding. The single average sounding can be used directly in order to obtain an equivalent volume from the vessel’s tank ullage calibration tables

Such a method will provide a clearer indication as to the type and nature of the residues on the cargo tank floor as well as provide much clearer indications as to the profile of the residues within the cargo tanks.

Source: nautraj.blogspot.com

We’ll be presenting a series of posts exploring answers to some of our most frequently asked questions (FAQs). Some will be useful to our distributors in determining what products to order for specific applications, or to educate their customers. Some will speak to the professional user who needs information on key features and benefits, or best practices in the use of a tool. Some will help our end-users to get the most out of the tool they just purchased. Some answers will simply be ‘fun facts to know and tell’ about measuring products.

This post will deal with a FAQ from our Oilfield sector regarding oil gauging tape.

What is the difference between Innage and Outage oil gauging tapes?

Surprisingly, we get asked this question a lot.

I would have thought, if you needed one of these measuring devices, you would know which one you need, since manual liquid or oil tank gauging is an activity undertaken by professionals, who have been trained in safety procedures and proper techniques. So, this question and answer is really geared towards distributors of products generally used in the oil and gas industry.

Now, back to Innage vs. Outage…

Simply stated, there are 2 techniques to manually gauge the level of liquids in a large storage tank using a tank gauging tape measure-Innage or Outage. Innage is the more prevalent technique used.

The Innage Method

The Innage method will tell you the actual depth of the liquid in the tank. An oil gauging tape measure with a plumb bob is lowered down from the reference point just to the point that the bob touches the bottom of the tank or datum plate. Care should be taken to lower slowly so the bob does not reach the bottom and then tilt over. This will cause an inaccurate measurement. Also, if the bob hits the bottom of the tank with too much force, it can damage or puncture the tank. (We have a new plumb bob that has a rubber end tip to help avoid this kind of damage).

When the tape is reeled back up the depth of the liquid in the tank is read where the tape is wet (like a dipstick in a car). Sometimes water-finding paste or petroleum paste can be used to help show the mark in very thin liquids. Innage oil gauging tapes are used with Innage plumb bobs. The zero point of an Innage gauging tape is at the bottom of the bob.

The Outage Method

The Outage (or Top gauging) method will tell you the measurement of the part of the tank that is NOT filled with liquid (the level that has been taken out, or the “ullage”). Because the exact top of the liquid is hard to find, the graduated plumb bob is lowered slowly from the reference point just until it comes into contact with the liquid. Outage gauging tapes are used with an Outage plumb bob.

The graduations on the outage plumb bob start at the point where the bob is attached to the swivel end clip of the gauging tape, and then get higher. The zero point on an Outage gauging tape is where the plumb bob and the end clip of the gauging tape meet. The reading on the bob (marked by the liquid) is added to the reading on the tape at the reference point (at the top of the tank). This will give you the total empty portion of the tank. Knowing the total depth of the tank, you can subtract the space NOT filled, from the total tank depth to determine the depth of the liquid.

The Outage gauging method is helpful when measuring caustic or thick liquids, as the actual tape measure blade never gets submerged but it is not as accurate as the Innage method for determining the actual level of liquid in the tank.

Choosing Oil Gauging Tape

So, now you know a bit more about manual tank gauging and some of the nuances of Innage vs. Outage measuring and be better able to stock the proper gauging tapes and bobs for your customers. We offer gauging tapes in lengths from 18’ to 100’, in measurement scales including 8ths, 10ths, 16ths, metric, and English/metric. We also have different blade styles (chrome plated, double duty, black etched, and etched stainless steel) for the varied liquids these gauging tapes will be used for. We have a large selection of plumb bobs to accompany them.

See our wide range of gauging tapes, plumb bobs, and accessories on our two websites: USTape.com and OilGaugingTapes.com. You can use the Contact Us form on either site if you have specific questions that you haven’t found answers to.

Tank Ullage Calculation

Future posts will explain the features and benefits of the variety of blade types we offer.